Pilot plant

Pilot Plant Base

The pilot plant base was established in 2016 to meet various needs encountered in engineering projects, providing a basis for the reasonable selection of process parameters for project schemes; exploring and verifying process routes; and providing theoretical analysis and data support for on-site problems.

Pilot plant equipment includes: microfiltration test unit, ultrafiltration test unit, rapid oil removal unit, precision oil removal unit, subcritical water oxidation unit, and MVR pilot plant. The pilot plant equipment can simulate on-site process conditions for testing, obtain accurate process operating parameters, and verify the operation effects of new processes and equipment on-site.

Pretreatment Pilot Module

Microfiltration Test Unit

An automatically operated microfiltration system that can test the adaptability of different microfiltration products to different treatment processes and can perform online testing of parameters such as temperature, flow rate, turbidity, PH, SDI, and pressure difference.

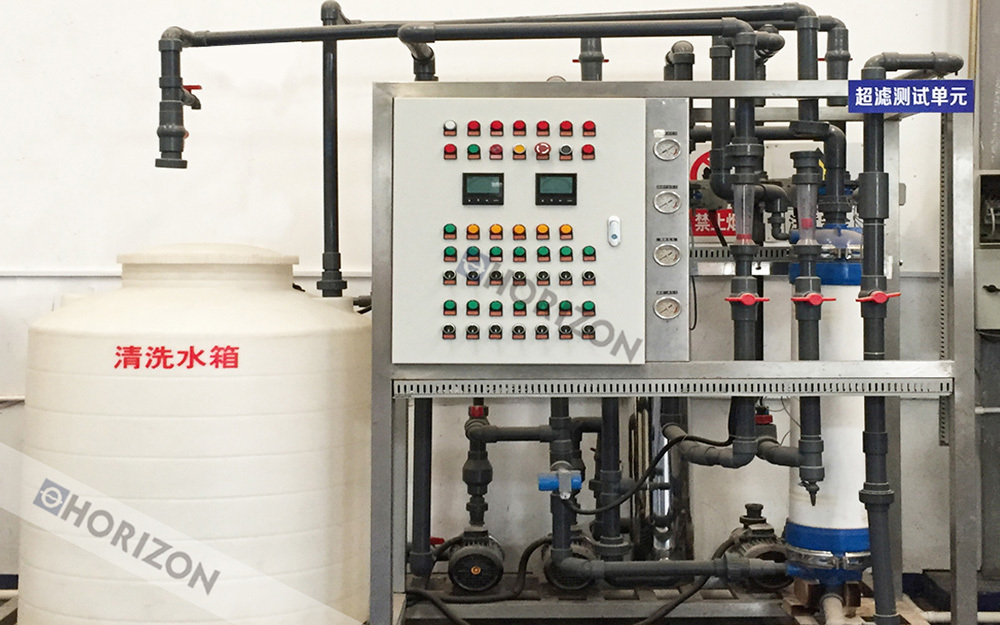

Ultrafiltration Test Unit

An automatically operated ultrafiltration system that can conduct performance and comparative tests of security filter cartridges and can perform online testing of parameters such as temperature, flow rate, turbidity, PH, SDI, and pressure difference.

Rapid Oil Removal Unit

Used for rapid oil removal of water samples with high oil content and relatively low oil removal requirements, and for pilot testing of on-site oil removal system processes. It can achieve a comparison of the experimental effects of different oil removal processes.

Precision Oil Removal Unit

Used for oil removal of water samples with low oil content and high oil removal precision requirements, and for pilot testing of on-site oil removal system processes. It can achieve a comparison of the experimental effects of different oil removal processes.

COD Treatment Module

Subcritical Water Oxidation Unit

The critical pressure and critical temperature of water are 22.1 MPa and 374.3 ℃, respectively. Water in a liquid state at a slightly lower temperature and pressure than 374.3 ℃ and 22.1 MPa is called "subcritical water". In the subcritical state, water changes from strongly polar to nonpolar, and its chemical properties become more active.

Subcritical water oxidation technology oxidizes organic matter and toxic substances in water, oxidizing organic matter into water, carbon dioxide, nitrogen, and inorganic salts. Some wastewater contains pollutants that are man-made substances, such as polycyclic aromatic hydrocarbons, heterocycles, and long-chain alkanes, or heterocyclic compounds containing nitrogen, oxygen, sulfur, and phosphorus. These substances have high stability, toxicity, and are difficult to treat. General treatment methods are difficult to effectively treat them. These wastewaters can be treated with subcritical water oxidation technology to achieve good treatment effects.

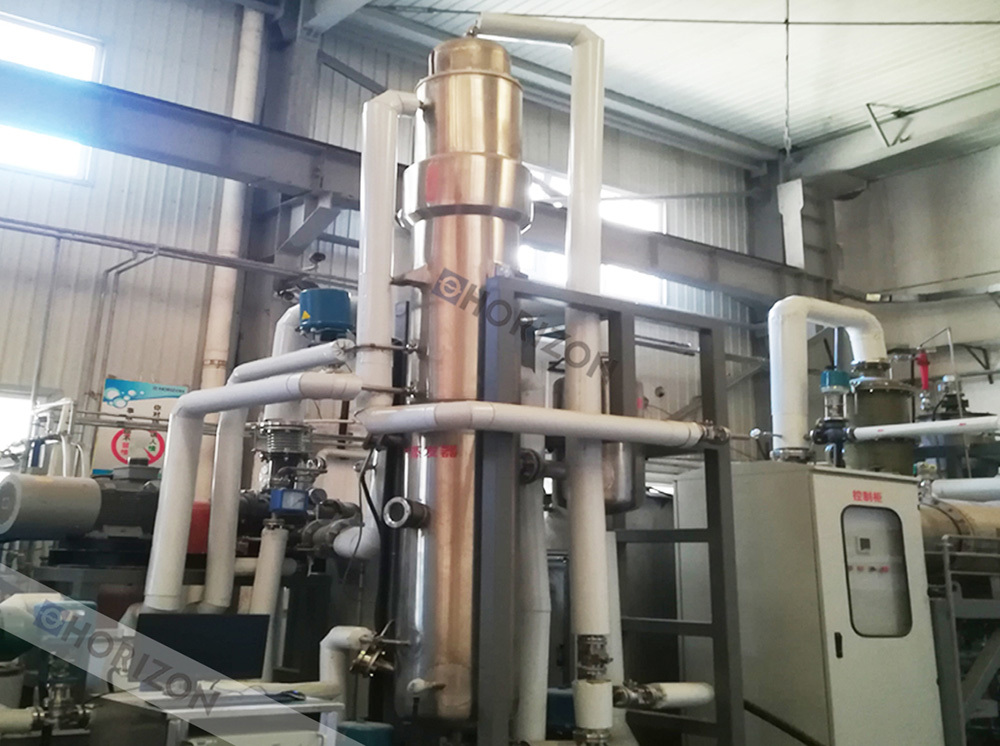

MVR Pilot Module

MVR fixed-type evaporation equipment functions: exploration of material evaporation and crystallization parameters; simulation operation of actual on-site problems; testing platform for new components.

MVR fixed equipment function: MVR mobile equipment function: experiment and testing of on-site problems; confirmation of the main engineering process ideas.

Process Parameters:

--Evaporation capacity: 200~500kg/hr

--Inlet water salinity: 3%~20%

--Crystal salt purity: >97.5%

--Crystal salt water content: <5%