Manufacturing base

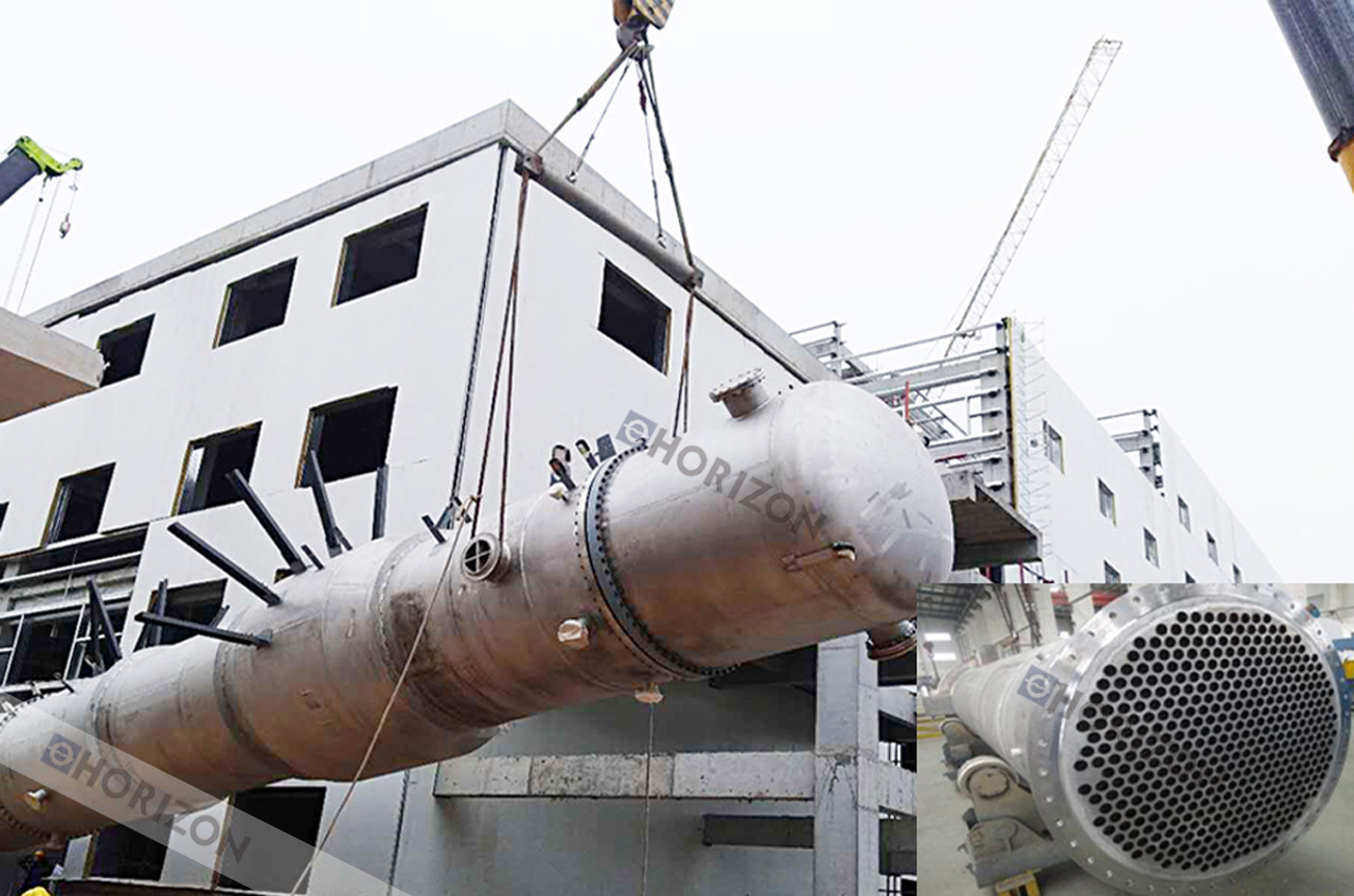

The manufacturing base is located in Zhejiang, covering a total area of approximately 90,000 square meters. It has 55,000 square meters of production workshops and multiple process production lines, including welding, equipment assembly, insulation, sandblasting and rust removal, pickling and passivation, testing, and painting.

The manufacturing base possesses advanced domestic and international mechanical processing and testing equipment, new materials, and new technologies. It integrates product R&D, mechanical processing, and assembly, providing complete sets of process design and equipment processing and manufacturing for the evaporation, crystallization, and filtration fields involved in zero-discharge industrial wastewater treatment technology. It offers customers unparalleled design and manufacturing solutions in terms of cost and quality.

The manufacturing base operates strictly in accordance with the requirements of the ISO9000 international quality management system. Its rigorous internal quality control system has been audited and approved by Bureau Veritas (BV), fully complying with the ISO9001:2008 international quality management system standard. It has also obtained numerous product certifications from domestic and international markets.

Quality Assurance

Ø ISO 9001:2008, Quality Management System audited by BV

Ø ASME Section VIII, Division 1 (including U stamp, NB stamp, and R stamp) quality assurance system, quality assurance system audited by ASME

Ø PED European Pressure Equipment Directive 97/23/EC quality assurance system, H mode, CE certified product, quality assurance system audited by UK HPI (NB1521)

Ø China Pressure Vessel Quality Assurance System (Category III, including design license and manufacturing license), quality assurance system audited and approved by the State Administration for Market Regulation

Ø ISO 3834-2 Welding Quality Management Quality Assurance System (Welding Factory Certification)

Quality Control

Ø Design

Ø Materials

Ø Welding Process

Ø Process Control

Ø Non-destructive testing, including RT, UT, PT, MT, and VT

Ø Material Reliability Identification (PMI) Testing

Ø Mechanical Performance Testing

Ø Coating Inspection

Main Equipment and Facilities

The manufacturing base is equipped with advanced equipment and facilities and has extensive manufacturing experience. All manufacturing activities are carried out under the supervision of the quality control department. The main equipment includes:

Ø Cutting equipment: Plasma, CNC flame cutting, laser cutting, shearing machine;

Ø Edge planing equipment;

Ø Bending equipment;

Ø Plate rolling equipment;

Ø Machining equipment;

Ø Manual, semi-automatic, and automatic welding equipment: GMAW (Gas Metal Arc Welding), GTAW (Gas Tungsten Arc Welding), SAW (Submerged Arc Welding), SMAW (Shielded Metal Arc Welding), and FCAW (Flux-Cored Arc Welding);

Ø Tube expanding machine;

Ø Sandblasting facilities;

Ø Spray painting facilities: Traditional spraying and airless spraying;

Ø Inspection equipment: VT (Visual Inspection), RT (Radiographic Testing), UT (Ultrasonic Testing), PT (Penetrant Testing), MT (Magnetic Particle Testing), leak testing, and coating inspection;

Ø Maximum single hoist lifting capacity up to 75 tons.

Qualification Certificates