The application of antibacterial filter cartridges in reverse osmosis pre-treatment security filters

Published Time:

2021-09-14

Source:

Author:

Application of bacteriostatic filter cartridges in reverse osmosis pre-treatment security filters

In pretreatment systems using reverse osmosis membranes, to ensure the normal operation of the reverse osmosis components and reduce the operational risks of the reverse osmosis system, inlet water is usually set before the reverse osmosis components Fiberglass security filter Filter cartridges are installed inside the security filter. Under pressure, the raw liquid passes through the filter cartridge, pollutants are intercepted by the filter cartridge, and the filtrate flows out through the filter material, thus achieving the purpose of filtration.

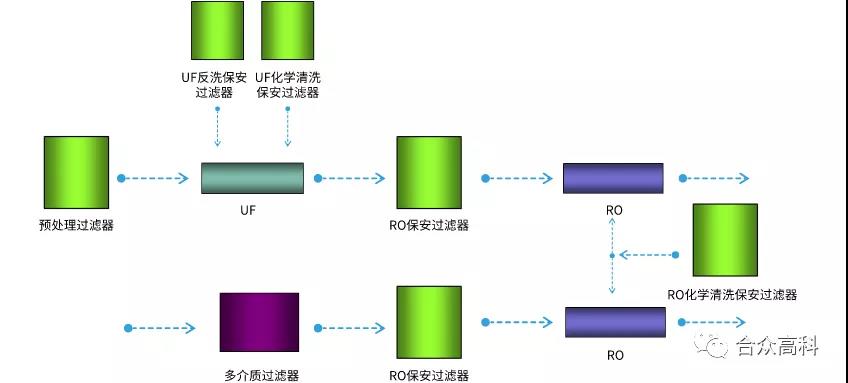

Position of the security filter in the system

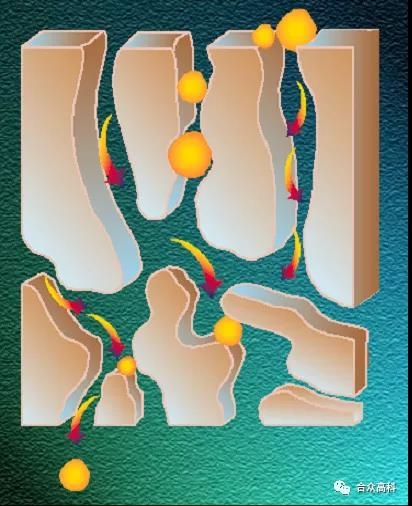

The essence of filter cartridge filtration is a kind of sieving. The filter cartridge can directly intercept pollutants larger than its pore size, and some small-particle pollutants will also be intercepted by bridging, thus playing a filtering role.

Interception filtration

As the intercepted pollutants continue to increase, the filter cartridge's flow area decreases, the filter cartridge's water output decreases, and the pressure difference between the filter cartridge inlet and outlet increases. When the filter cartridge pressure difference reaches the replacement value, the filter cartridge needs to be replaced. Otherwise, the low water output will have an adverse effect on the reverse osmosis high-pressure pump, and the high pressure difference may damage the filter cartridge, causing adverse effects on the system operation. Colloids, particles, and microorganisms in the water will all cause clogging of the filter cartridge, and microbial clogging is serious.

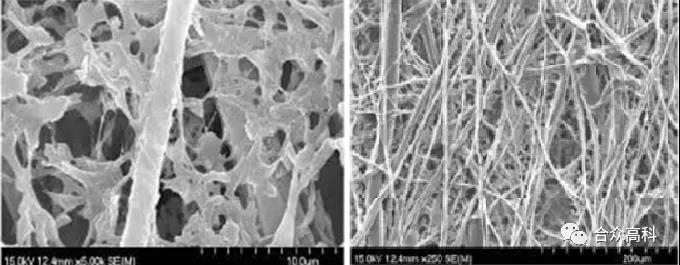

Microstructure of filter material

From the microstructure of the filter material, we can see that the filter cartridge relies on countless "flow channels" formed by fibers for filtration. Pollutants with a particle size larger than the diameter of the flow channel are intercepted. Microbial pollution is not like ordinary particulate pollution, which slowly accumulates in the flow channel. Microorganisms are sticky on the surface of the filter cartridge, and they reproduce rapidly, adhering between the channels formed by the fibers, "blocking" the channels.

Microbially contaminated filter cartridge

Microbial contamination under electron microscope

There are three main reasons for microbial contamination of the system: firstly, insufficient sterilization treatment in the pretreatment stage, and microorganisms reproduce and gather again in a suitable environment; secondly, the system process flow, such as systems using activated carbon filters, the residual chlorine after the activated carbon bed is removed, reaching Fiberglass security filter Microorganisms cannot be killed, and a large number of microorganisms gather in water tanks, pipelines, and security filters, becoming the source of microbial contamination of fiberglass security filters and reverse osmosis membranes; thirdly, the system is shut down for a long time, and the stagnant water provides a better environment for the aggregation and reproduction of microorganisms in the water.

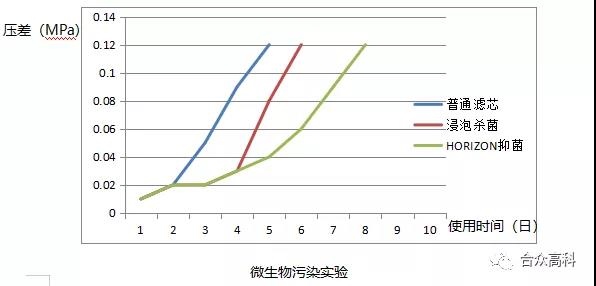

To solve the problem of rapid pressure increase and short service life of filter cartridges due to microbial contamination, some manufacturers use the method of soaking filter materials in bactericides. This method is simple to operate and low in cost, but the amount of drug release during use will rapidly decay, resulting in a large amount of medicine in the early stage and "no medicine available" in the later stage.

The company hired relevant experts and cooperated with pharmaceutical manufacturers, filter material manufacturers, and university laboratories to conduct a large number of experiments to overcome the difficulties of drug and filter material fusion and stable drug release, and determined the bacteriostatic filter cartridge materials and production plan, solving the problem of uneven release of bactericides or even water pollution. Experiments have shown that our bacteriostatic filter cartridges have a significant bacteriostatic effect in actual microbial contamination conditions, slowing down the pressure increase and extending the service life.

From the above figure, it can be seen that the clogging of the filter cartridge by microorganisms is different from that of particulate matter. Once microbial contamination occurs, the clogging speed of the filter cartridge is very fast. The bacteriostatic effect of the HORIZON bacteriostatic filter cartridge manufacturing process is significantly better than the other two filter cartridges, effectively extending the service life of the filter cartridge. Of course, the bacteriostatic filter cartridge is not a sterilizing filter cartridge. The greater role of the bacteriostatic filter cartridge is to prevent the massive reproduction of microorganisms on the surface of the filter cartridge, directly clogging the filter cartridge, while the effect of eliminating existing microorganisms in the water is very limited.

Recommended Dynamics