Good News | Warm Congratulations on the Publication of Our Company's Technical Achievement Paper in "China Well Mine Salt"

Published Time:

2021-01-29

Source:

Author:

Warmly celebrating the publication of Hezhong Company's research results and technical papers in the core journal "China Well and Mine Salt"

Published Journal Number: Vol. 51, No. 6, 2020

Article Title: Analysis of the Technological Route of Energy-Saving Salt Making Process for Gypsum-Type Brine

Hezhong Company focuses on innovation and new technologies, develops new processes and products, attaches importance to R&D investment, and has continuously made breakthroughs in research results. It has now developed into a world-class provider of zero-discharge wastewater solutions and membrane equipment supplier.

This research paper analyzes the technological route of energy-saving salt making process for gypsum-type brine. It proposes the use of a six-effect counter-current feed circulation patented technology process route for research and analysis by peers.

Publication Details

Magazine Article Internal Publication

Original Text Concise Content Introduction

Analysis of the Technological Route of Energy-Saving Salt Making Process for Gypsum-Type Brine 》

Concise Main Text:

I. Analysis of Energy-Saving Salt Making Process for Gypsum-Type Brine

1.1 Preface

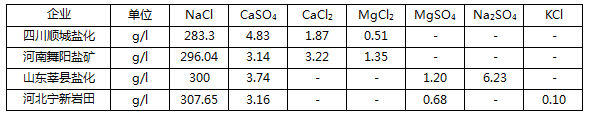

Gypsum-type brine mainly contains sodium chloride, with a small amount of impurities such as calcium sulfate. The composition of gypsum-type brine is shown in Table 1.

Table 1 Composition of Gypsum-Type Brine

According to the dissolution law of the above inorganic salts, the solubility of sodium chloride, magnesium sulfate, sodium sulfate, calcium chloride, and magnesium chloride is large, while calcium sulfate is slightly soluble. Therefore, there are major process problems in the evaporation and salt making process: premature supersaturation and precipitation of calcium sulfate; during the brine preheating process, when the temperature is higher than 70 degrees, calcium sulfate precipitates and scales, making descaling of the heat exchange equipment difficult, affecting its use and further improvement of the preheating temperature. Therefore, the improvement of thermal economy in gypsum-type brine salt making evaporation is limited.

1.2 Analysis of the Main Energy-Saving Process Routes for Gypsum-Type Brine Evaporation and Salt Making

1.2.1 1 Million-Ton Salt Making Project Case - Analysis of the Process Route of Lime-Mirabilite Flue Gas Purification Brine and Six-Effect Evaporation Salt Making Process

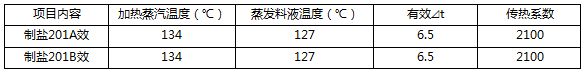

Process flow: Brine and salt making mother liquor are mixed, lime is added in the first stage to remove magnesium, and flue gas is added in the second stage to remove calcium. Refined brine heat exchange, steam-water heat exchange, parallel flow feed, co-current material transfer, parallel flow salt discharge. Relevant parameters of the salt making system are shown in Table 2.

Table 2 Technical Parameters of Salt Making Evaporation Process

1.2.2 600,000-Ton Salt Making Project Case - Analysis of the Process Route of Lime-Mirabilite Flue Gas Purification Brine and Mechanical Compression Evaporation Salt Making Process

Process flow: Brine and salt making mother liquor are mixed, lime is added in the first stage to remove magnesium, and flue gas is added in the second stage to remove calcium; the refined brine is heat exchanged with cooling water and enters the mechanical compression evaporation salt making process near the boiling point, and the salt making mother liquor is recycled to the brine purification system. The amount of refined brine entering and leaving the mechanical compression evaporation tank is artificially controlled and reduced, and the selection of refined brine sodium sulfate 14g/l requires the consumption of some soda ash; the addition of soda ash produces some sodium sulfate entering the mine and large-scale production cycle. Operating parameters of mechanical compression evaporation salt making are shown in Table 3.

Table 3 Technical Parameters of Mechanical Compression Salt Making Evaporation Process

According to the above analysis of gypsum-type brine process, the purification of raw brine increases the cost; this paper proposes a patented technology process route of six-effect evaporation salt making with counter-current circulation of gypsum-type brine to solve the problem of gypsum scaling in the salt making preheating process, so as to achieve the purpose of energy saving, consumption reduction, investment reduction, and cost reduction.

II. Analysis of the Patented Technology Process of Six-Effect Evaporation Salt Making with Counter-Current Circulation of Gypsum-Type Brine for 1 Million-Ton Salt Making Project Case

2.1 New Energy-Saving Salt Making Process

Process route: Gypsum-type brine uses cooling water heat exchange, counter-current feed of brine, six-effect evaporation salt making, and lime removal and recovery of magnesium from salt making mother liquor.

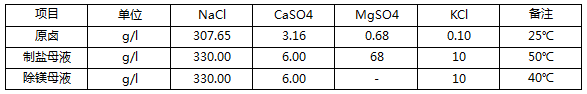

Gypsum-type brine: Relevant components of gypsum-type brine from Hebei Ningxin Yantian Chemical Co., Ltd. are shown in Table 4.

Table 4 Composition of Gypsum-Type Brine

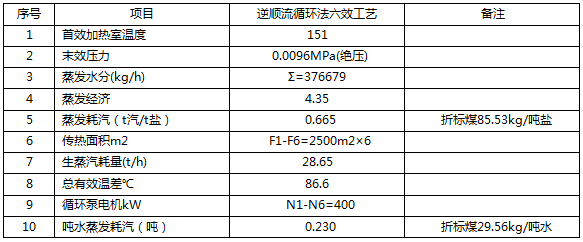

Salt making process calculation results: The salt making process calculation results are shown in Table 5.

Table 5 Evaporation Salt Making Calculation Results Table 1 Million Tons/Year Scale

III. Preliminary Conclusions of Process Analysis

According to relevant data analysis of 1 million-ton salt making equipment, the patented technology process of six-effect evaporation salt making with counter-current circulation of gypsum-type brine:

1) Energy consumption level analysis: The evaporation thermal economy is as high as 4.35, and the steam consumption for evaporation per ton of salt is 0.665 tons, reaching the industry-leading level.

2) Equipment cost analysis: Compared with the lime-mirabilite flue gas purification brine process, investment is reduced.

3) Production cost analysis: Compared with the lime-mirabilite flue gas purification brine process, brine treatment cost is saved.

4) Comprehensive evaluation analysis: This process route has low energy consumption, low investment, and high efficiency.

Hezhong High-Tech (Beijing) Environmental Protection Technology Co., Ltd.

Hezhong Si (Beijing) Environmental Engineering Co., Ltd.

Provider of zero-discharge wastewater solutions and membrane equipment supplier. We provide professional water treatment equipment and integrated solutions for the power, coal chemical, petroleum, chemical, metallurgical, mining, and municipal industries at home and abroad, including process consultation, engineering design, equipment procurement, construction management, and after-sales service.

Leveraging our rich practical experience, we adhere to the principle of providing "affordable equipment and technology, mainstream technology, and mature processes." Our comprehensive and systematic management of the entire engineering operation process effectively reduces water treatment costs for our clients. We have provided products and engineering services to over 1000 clients in 50 countries.

Recommended Dynamics